- Savage Blog

- How Rifling Works: Button Rifling, Twist Rates & More

How Rifling Works: Button Rifling, Twist Rates & More

Rifling might be one of the most overlooked aspects of a rifle’s design, yet it plays a central role in a firearm's performance. Those spiraled grooves inside the barrel do more than look interesting—they stabilize the bullet, improve accuracy, and can make or break your shot placement. Understanding how barrels are rifled, how twist rate affects your bullet, and the difference between rifling methods gives shooters a clearer picture of what makes a precision rifle. And when it comes to rifling, Savage Arms has perfected the process to put accuracy at the forefront.

What Is Rifling and What Does It Do?

Rifling refers to the helical grooves cut or formed inside the bore of a barrel. As a bullet travels through these grooves, they impart a spin on the projectile. This spinning motion is what stabilizes the bullet in flight, preventing it from tumbling and keeping its nose pointed forward.

Why does this matter? Stabilization greatly enhances a bullet’s accuracy and consistency downrange. The spin creates gyroscopic stability, helping the bullet resist deflection from air resistance and minor imperfections. In short, rifling is what makes a firearm truly accurate.

Cut vs. Button Rifling

Two of the most common rifling methods are cut rifling and button rifling.

Cut Rifling involves removing material from the barrel’s interior using a cutting tool. This method is slower and is often used in custom applications. It allows for fine control over the rifling dimensions and is ideal for specialty barrels or unconventional twist rates.

Button Rifling, on the other hand, uses pressure to form the grooves in a single pass. It’s fast, repeatable, and excellent for large-scale production without sacrificing accuracy.

Savage Arms uses button rifling because it delivers precision and repeatability at scale. Every rifled barrel undergoes rigorous inspection to ensure each groove and land is dimensionally consistent. This perfected method, used across a high volume of production, is one of the reasons for Savage’s reputation for building highly accurate rifles trusted by hunters and shooters alike.

How Savage Barrels Are Rifled

The process of adding rifling to a barrel varies by manufacturer and technology. There are several ways to create rifling, and each method has its strengths.

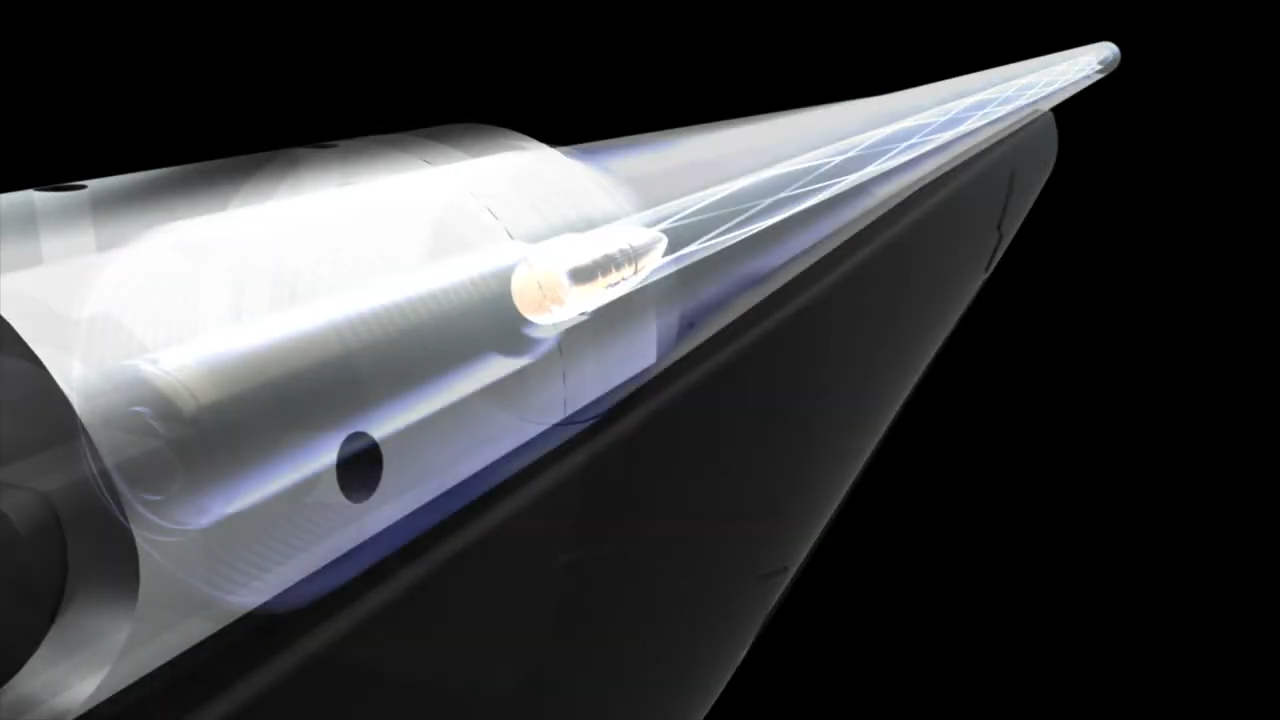

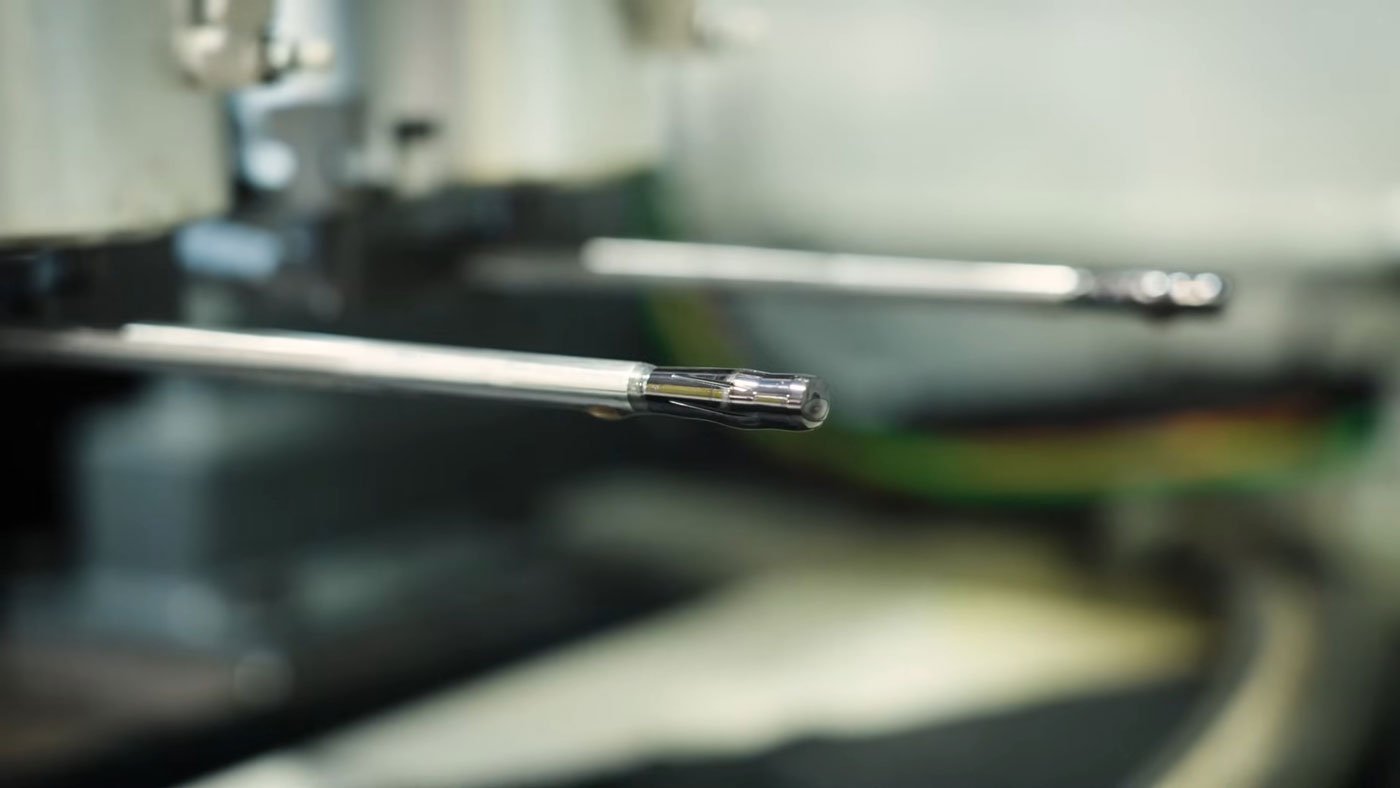

At Savage Arms, the preferred method is button rifling. In this process, a tungsten-carbide button with the reverse geometry of the rifling is pulled through a pre-drilled and reamed barrel blank. The button applies extreme pressure as it passes through, displacing the steel and forming the lands and grooves without cutting material away.

This cold-forming process does more than shape the rifling—it work-hardens and smooths the steel at a microscopic level. The result is a consistent and uniform internal finish that helps minimize bullet deformation, reduce fouling, and promote consistent velocities. Button rifling is fast, scalable, and produces barrels capable of outstanding accuracy—a core value of every Savage firearm.

Barrels are then inspected for uniformity, twist rate consistency, and dimensional accuracy before moving on to chambering and final assembly.

Understanding Twist Rate

Twist rate refers to the rate at which the rifling spins the bullet. It’s typically measured in inches per turn—for example, a 1:10 twist means the rifling completes one full rotation every 10 inches.

Why does twist rate matter? Because different bullets require different rates of spin to stabilize properly. Heavier or longer bullets need a faster twist (lower ratio), while lighter bullets can use a slower twist (higher ratio). A mismatch can result in poor accuracy or unstable flight.

Some general examples:

1:10 twist: common for .308 Win (150gr to 180gr)

1:8 twist: versatile for 6.5 Creedmoor (120gr to 147gr)

Savage matches twist rates to the intended caliber and purpose of each rifle. In the .30 caliber family, different twist rates are optimized for different uses:

1:8 twist – Ideal for .300 Blackout shooting heavy subsonic loads, where a faster spin is needed to stabilize slower-moving, heavier bullets.

1:8.5 twist – Common for .300 PRC, stabilizing some of the longest .30 caliber bullets (up to 245 grains) for long-range precision.

1:10 twist – Standard in .308 Win and .30-06 Springfield, offering excellent accuracy with a broad range of bullet weights, making it highly versatile.

Whether you're shooting small game with a rimfire or dropping elk at long range with a centerfire, the twist rate is optimized for the cartridge you’ll be using.

Why Rifling Matters in the Field

Quality rifling ensures that bullets spin correctly every time, offering more consistent trajectories and tighter shot groups.

Hunters benefit from reliable shot placement, whether taking ethical shots on game at a distance or following up on a moving target. Target shooters appreciate the precision that quality rifling delivers over long strings of fire. When your rifle’s barrel is properly rifled and matched to the right twist rate, everything from zeroing to first-round hits becomes more predictable.

Savage rifles are known for their out-of-the-box accuracy, thanks in large part to button-rifled barrels that have been precisely finished and tested.

Rifling and Savage Arms Manufacturing

At Savage Arms, rifling isn’t just a production step—it’s a defining part of our reputation. Our in-house barrel production gives us precise control over tolerances, tooling, and twist rates, allowing us to build rifles known for their accuracy.

Using button rifling, Savage produces a highly uniform internal surface that minimizes bullet deformation and reduces fouling. The cold-forming process helps maintain material integrity, which in turn supports longevity and consistent performance.

Every barrel is checked for consistency and dimensional accuracy. Barrels are stress-relieved after rifling to maintain straightness. Combined with Savage’s zero-tolerance headspacing and floating bolt head design, the rifling process becomes part of a system engineered for precision.

The result? Savage rifles that consistently outperform expectations in the field, on the range, and in competition.

Rifling is at the heart of every accurate shot. From stabilizing your bullet to optimizing your barrel for a specific cartridge, rifling makes all the difference. The method of rifling—especially button rifling—along with correct twist rates, plays a key role in a rifle’s final performance.

Savage Arms takes this seriously. With precision manufacturing and in-house control over barrel production, Savage ensures that every rifle meets high standards for consistency and accuracy. Whether you're a hunter, competitor, or weekend shooter, rifling is one of those hidden details that elevates performance—and Savage makes it a priority in every gun that leaves the factory.